Bearing Elements

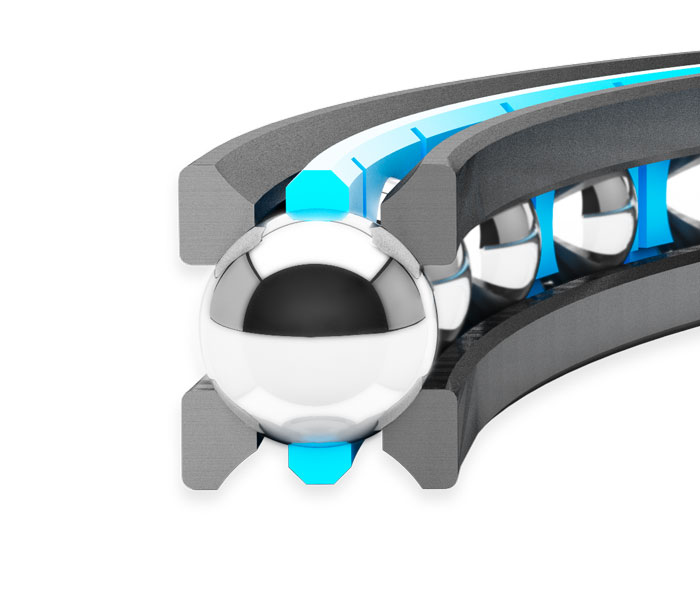

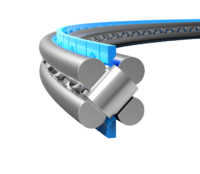

Franke Wire Race Bearings are based on a simple yet ingenious principle: Individual race rings made of wire are fitted with a raceway that is designed precisely to match the diameter of the rolling elements. Therefore, the rolling action does not take place directly between the rolling elements and mating structure, but rather with low-friction on the four open race rings. This engineering principle permits free design of the mating structure in terms of its geometry and material selection.

Profile Table

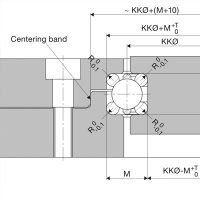

LEL – Ground Raceway

Bearing Type

- 4 Race rings with ground raceways

- Plastic ball cage with retained balls

- Franke bearing elements in type LEL meet high standards in terms of runnability and accuracy. Their hardened and CNC-ground raceways, along with the ideal geometric adjustment of ball and raceway radius, lend them outstanding bearing properties. Bearing elements in the LEL type permit the greatest possible freedom of bearing design. The standard mounting space is between 5.9 mm and 20.9 mm. Race ring thickness of up to 20 mm and bearing sizes up to 50 mm are possible to meet special requirements.

Characteristics

- Maximum possible integration capacity

- Series application to meet cost constraints

- Greatest possible flexibility based on preload, runnability and diameter ranges

- Bearing elements of the LEL type consist of two inner and two outer raceways, along with a plastic cage with retained balls. The race rings are divided at one point to compensate for the temperature expansion factor. They possess compensatory properties for demanding forms of stress. LEL are generally mounted free from clearance. The preload can be defined individually to meet the specific requirement. See ‘Technical information’ for the adjustment methods.

Diameter Range

- Infinitely variable from 70 to 2000 mm

Mating Structure

The bearing element mounted determines the overall construction’s load bearing capacity. Hence the mating construction can be made of alternative materials such as steel, aluminium or plastic. Axial and radial accuracy are defined to a substantial extent by the mating components. These properties can be enhanced by boosting the accuracy of manufacture.

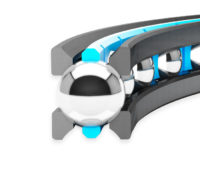

LER – Rectangular profile/profiled raceway

Bearing Type

- 4 race rings with profiled raceways

- Plastic ball cage with retained balls

- Franke bearing elements in type LER are designed for medium rotational speeds and accuracies. They run smoothly, possess high dynamism and require just compact mounting space. The straight contact surface ensures simple integration in the mating structure and also a high rigidity. The attractive price makes this bearing element type LER an economic solution.

Characteristics

- Maximum possible integration capacity

- Series application to meet cost constraints

- Greatest possible flexibility of preload, runability and diameter ranges

- Bearing elements of the LER type consist of two inner and two outer raceways, along with a plastic cage with retained balls. The race rings are divided at one point to compensate for the temperature expansion factor. They possess compensatory properties for demanding forms of stress. LER are generally mounted free from clearance. The preload can be defined individually to meet the specific requirement. See ‘Technical information’ for the adjustment methods.

Diameter Range

- Infinitely variable from 70 to 2000 mm

Mating Structure

The bearing element mounted determines the overall con- struction’s load bearing capacity. Hence the mating con- struction can be made of alternative materials such as steel, aluminium or plastic. Axial and radial accuracy are defined to a substantial extent by the mating components. These properties can be enhanced by boosting the accuracy of manufacture.

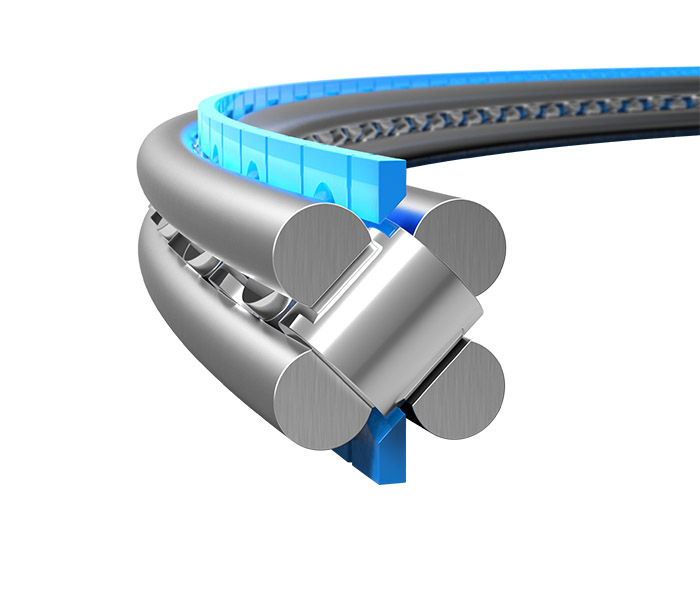

LEW – Cross roller bearing/ground raceways

Bearing Type

- 4 race rings with ground raceways

- Plastic cage with rollers

- Franke bearing elements of the type LEW are suitable for medium rotary speeds and accuracies. They impress with their smooth running, high stiffness and compact installation space. The crosswise arranged rollers absorb the same high loads from all directions. Bearing elements type LEW are robust and insensitive to shocks and vibrations.

Characteristics

- Maximum possible integration capacity

- High stiffness

- Greatest possible flexibility of preload, runability and diameter ranges

- Bearing elements type LEW consist of two inner and two outer races and a plastic cage with rollers. The race rings are split in one place to compensate for temperature expansion factors.They have balancing properties in demanding types of stress. LEW are usually installed without backlash. Depending on the requirements, the preload can be adjusted individually. For tuning methods see “Technical Information”.

Diameter Range

- Infinitely variable from 400 to 1200 mm

Mating Structure

The built-in bearing element determines the load capacity of the overall construction. The enclosing construction can therefore consist of alternative materials such as steel, aluminum, plastic. Planarity and concentricity are largely defined by the enclosing parts.Increased manufacturing accuracy can further improve these values.

4 Point Principle

Our Wire Race Bearings are based on a simple yet ingenious principle: Individual race rings made of wire are fitted with a raceway that is designed precisely to match the diameter of the rolling elements. Therefore, the rolling action does not take place directly between the rolling elements and mating structure, but rather with low-friction on the four open race rings. This engineering principle permits free design of the mating structure in terms of its geometry and material selection.

Wire Race Bearings are extraordinarily compact and fit snug in even the tiniest mounting spaces. They are available either as bearing elements (consisting of race rings, rolling element and cage), or as ready-to-use bearing assemblies together with the mating structure.

Advantages

Maximum design freedom, without compromising precision or load capacity.

Principle

4 Point ContactFreedom of Design

4 Point contact principle to take load from all directions. the rolling process does not take place directly between the rolling elements and the mating structure, but rather on special race rings, giving maximum freedom of design.

Compact

Minimal Mounting SpaceMinimal Mounting Space

Requiring only a small mounting space, the compact and highly resilient four-point geometry of Franke Bearings gives you maximum freedom of design, making an ideal design component for your application.

Material

Unlimited Material ChoiceUnlimited Material Choice

Franke lightweight aluminum bearings are 65% lighter than steel, offering substantial design freedom. Available in a wide range of materials, from aluminium, bronze ceramic, plastic, carbon, 3D printed and many more.

Bespoke

Built To Your ApplicationBuilt To Your Application

Available in sizes from 60 – 2000+ mm. 95% of our products are bespoke versions. Franke rotary solutions are always designed and built to fit your application. We work with you from concept, to prototype through to final testing.