Expert Interview: The customer gets a bespoke comprehensive set of lightweight bearing and drive system

Technology specialist Stefan Strobel is a technical consultant at Franke. In our expert interview he talks about opportunities and projects in the field of direct drive lightweight bearings. And about why he finds wire race bearings cool.

Mr Strobel, what is so special about wire race bearings with direct drive?

Stefan Strobel: The enormous variety of design options. Although other vendors have also directly motorized bearings in the program but we are able to customize geometry and material.

Why is this customization in your view so important?

Stefan Strobel: Because this creates additional value for the customer. Imagine,

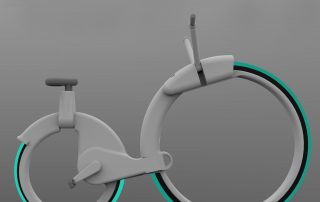

the bearing is to move a radar unit in the nose of your aircraft. We build it for you out of aluminum so that it withstands vibrations and temperature changes without any problems. Or think of the hub of an electric vehicle. We design the housing parts so that they conform to the shape of the rim on which you can draw your tires without further components. You won ´t need any components, adapter plates and similar additives. And that saves both: costs and weight.

Do your customers think about this in the same way?

Stefan Strobel: Absolutely.

For example?

Stefan Strobel: For example, the designer of an innovative electric vehicle. We have integrated a double-row angular contact ball bearing in the wheel, the motor is directly adapted and the tire is mounted directly on the outer ring of the bearing. The free center of the rim provides space for installing a braking system. The plan is to run all four wheels of the vehicle like is. Then all you need is a high-performance control unit, to coordinate the drives and a compact design power supply. Finished!

Of course, the entire rim is made of aluminum, reducing the weight of the vehicle. And the drive power has an easy time. Cool stuff, right?

No question – do you see further more potential for this technology?

Stefan Strobel: Vehicles are currently an interesting application. We have several projects at the start and at the trial here. Other sectors are the classic mechanical engineering – for example, in rotary indexing tables or tool changers – and the food and packaging industries.

Here we score with special materials and seals for the bearing housing to offer a compelling movement system in moist or aggressive environment. Other potential applications include aerospace, medical technology and robotics. Especially robotics deal more and more with small, lightweight designs for the workplace and in service. Here, the direct drive bearings could be small and powerful integra- ted directly into the bearings.

A wide field. You seem to rely on wire race bearings a lot …

Stefan Strobel: Of course. Throughout my young career at Franke I‘ve seen some spectacular applications for wire-race bearings and I must say the product is incredibly versatile. Whoever once has recognized the potential of this technology, can not help to become enthusiastic about it. “Light bearings for innovation” is our brand claim.

FRANKE BEARINGS SUPPORT THE UNIVERSITY OF MANCHESTER MASTERS ENGINEERING PROJECT

UNIVERSITY OF MANCHESTER MASTERS ENGINEERING PROJECT On Monday [...]

NEW CONTRACT WITH AWARD WINNING HUBLESS WHEEL ELECTRIC BIKE

NEW CONTRACT WITH AWARD WINNING HUBLESS WHEEL ELECTRIC BIKE [...]

DOWNLOAD THE NEW FRANKE BEARINGS CATALOGUE

NEW FRANKE BEARINGS CATALOGUE NOW AVAILABLE ONLINE Read [...]

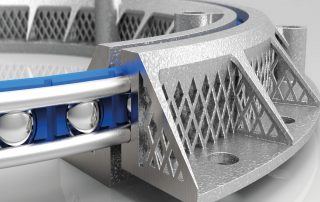

HOW ARE 3D HOUSING PARTS MADE?

HOW ARE 3D HOUSING PARTS MADE? Keen to [...]