Rotary Bearings – Frequently Asked Questions

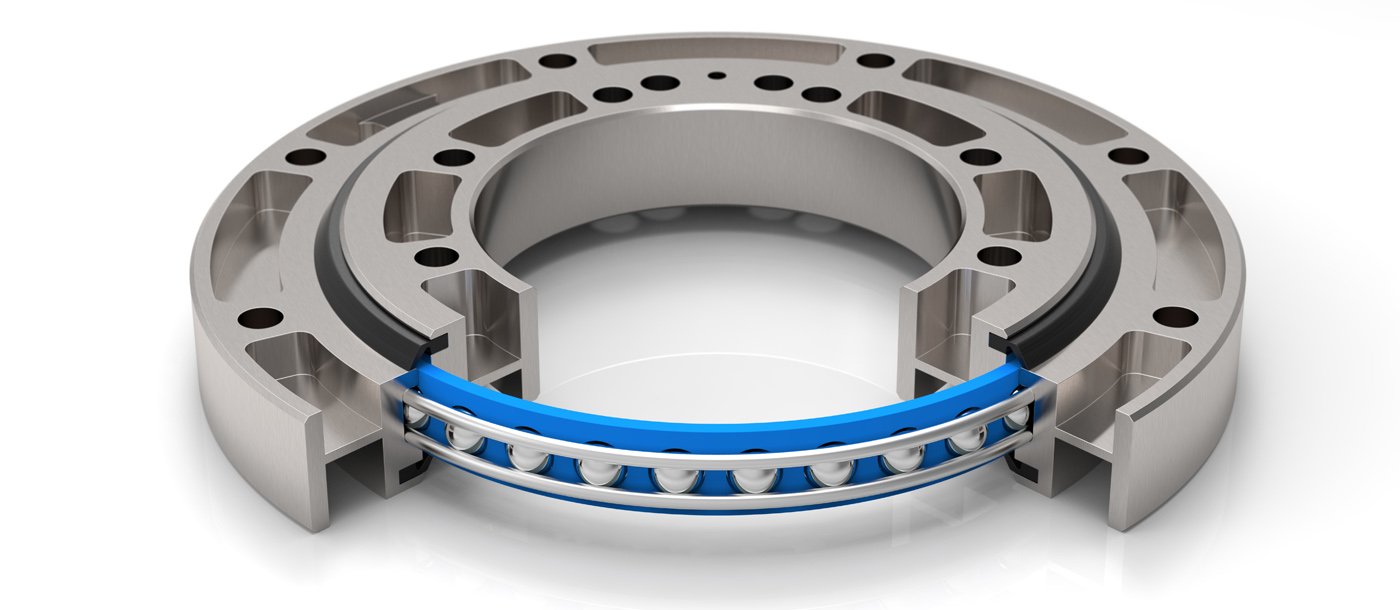

Franke bearing elements are available in a diameter range from 30 to 9.000 mm.

The diameter of Franke bearing assemblies can be freely chosen between 60 and 2000 mm.

The axial and radial accuracy depend, among other things, on the bearing diameter

and are defined to a substantial extent by the mating components.

These properties can be enhanced by boosting the accuracy of manufacture.

Bearing elements are preloaded free from clearance. The preload can be defined individually.

Slim bearings are not preloaded. They can be preloaded by ball sorting.

Bearing assemblies are preloaded free from clearance.

On request you can receive the bearing assemblies ex works with your specified preload values.

Franke wire race bearings can be aligned and adjusted using washers, solid adjustment or adjusting ring.

The exact procedure is detailed in the corresponding mounting instructions.

Our standard bearing assemblies can be modified according to customer requirements.

Please contact our technical support.

All lubricants are subject to an aging process which limits the service life.

For the initial lubrication of Franke wire race bearings, the Klüber ISOFLEX TOPAS NCA52 (KHC2 N-50) is used.

The age-resilience of this lubricant is about 3 years.

Alternatively, Shell Gadus S3 T100 is used for the initial lubrication.

The relubrication volume is dependent on the calculated empty space inside the bearing assembly.

The calculated volume must be filled with lubricant to 20 to 30 %.

30 to 40 % is recommended for swivel bearings.

You can find the formula for the calculation of the relubrication volume in the corresponding mounting instructions.

The lubricant quantity is dependent on the calculated empty space inside the bearing assembly.

For swivel bearings, the calculated volume must be filled with lubricant to 30 to 40%.

Depending on the circumferential speed and environmental influences:

| 0 to <3 m/s | after every 5000 h |

| 3 to <5 m/s | after every 1000 h |

| 5 to <8 m/s | after every 600 h |

| 8 to <10 m/s | after every 200 h |

The race rings are made of hardened spring steel and are therefore suitable for high loads as well as a high service life.

The hardness of the raceway is generally at 52 to 54 HRC (standard) or rather 43 to 46 HRC (non-corrosive).

The design and production differs for the various bearing elements and slim bearings.

You can find further details in our technical information.

The static axial radial moment load ratings, i.e. the dynamic axial and radial load ratings are required to deliver ideal design.

Furthermore, the rotational speed and ambient influences (e.g. temperature, moisture) as well as special operating conditions (e.g. clean room, vacuum) are required.

The mounting dimensions of Franke slim bearings are partially comparable to those of the bearings of other market players.

However, Franke bearings offer several advantages because of the wire race bearing technology.

Please let our technical support advise you.