Applications

With a collective knowledge and experience of over 75 years helping engineers innovate, our team strive to collaborate with our customers, to ensure we offer expert solutions for a wide variety of projects and applications.

Site Assessment

We offer on-site assessments to gain a full understanding of your problem and requirements.

Following a full assessment, we will discuss with all your relevant stakeholders your bespoke needs and concerns, so that we understand fully the criteria needed for your application.

From the first assessment you will receive concise answers, helpful communication and reliable information, giving you and your team real-time reactions to urgent problems.

Specification

With our industry specific knowledge, we are able to offer specialised solutions, adapted to your requirements.

We will explore all suitable options and assist you, working in partnership with your Design, Projects & Engineering teams, to offer simple, effective solutions in the form of bespoke, precision products from a quality industry recognised brand.

We offer unparalleled and flexible support, providing you with the optimum solution to each application.

Installation

Our specialist team are able to provide a unique installation and fitting service. Giving you the peace of mind that you only need to liaise with one trusted supplier, who understands your application and requirements.

We have vast experience working on various sites across the UK, supporting teams with their bespoke design and special purpose-built machines. We work across a wide range of sites and industries ranging from nuclear and aerospace through to automotive and manufacturing.

Linear Applications

Cutting with water jets calls for exact and rapid movements of the cutting head above the work piece, to create even and smooth edges to travel along even more complex geometries.

Solution

Franke Linear Motor module FTH Drive with integrated direct drive.

Advantages

Lightweight aluminium design for low weight and dynamic movement. The linear motor is integrated in the rail profile. This makes the module extremely flat and ensures it requires very little mounting space. The aluminium body and the non-corrosive running bars make the system insensitive to moisture.

Linear Guide used in secondary panel of the dental X-Ray device. Purpose of the panel is to enable exact X-Ray imaging. Primary requirement that the unit travels without any oscillation and the guide must run easily and smoothly.

Solution

FDL12 integrated directly into the customised carriage mount. A lateral grub screw used to set the slide resistance and the stiffness of the system. This guarantees movement without any oscillation.

Advantages

The guide runs evenly, quietly and cleanly. The elevated preload ().6 to ).8N) ensures that the secondary panel travels free from oscillation. The guide comes with lifetime lubrication. The sealed, single-row ball bearing means that no lubricant can leak to the outside.

Due to working at high speeds the linear guides needed must be resistant to aggressive materials (e.g salt, sugar, spray water). The machine had stoke lengths of 1500mm to 2100mm with an average annual mileage of 30,000km per year.

Solution

The aluminium roller guides in series FDA20

Advantages

The aluminium roller guides FDA enables speeds of up to 10m/s. The stroke lengths are infinitely variable. Central lubrication on the cassette achieves high service life and substantial mileage. Grease nipples fitted to the front, allow for convenient lubricant replenishment while the guides are fitted.

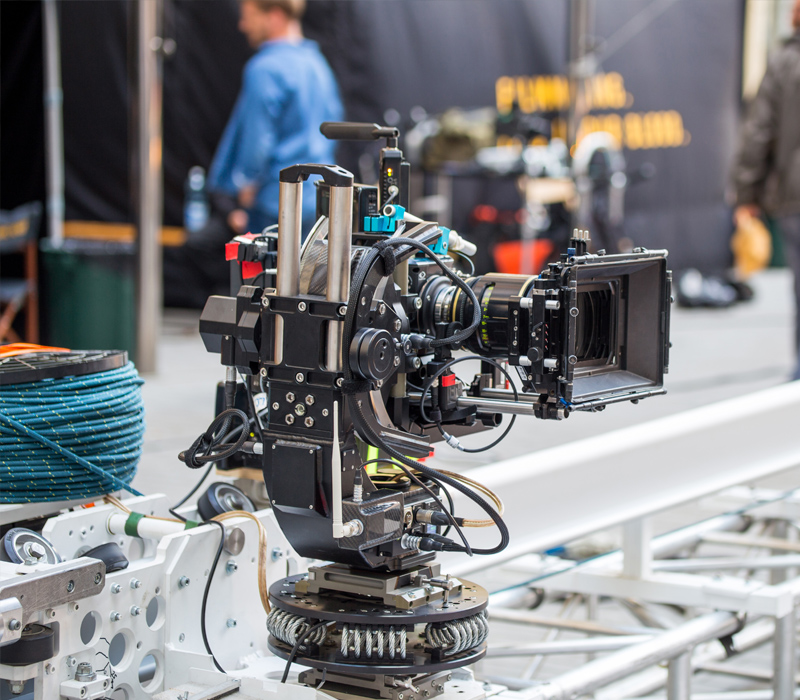

Quiet Operation, homogeneous movement and low weight.

Solution

Franke Linear Systems in a variety of lengths with accessories.

Advantages

Lightweight aluminium design for low carrying weight, large-scale rollers for smooth and quiet running and a broad range of accessories to adapt in a variety of shooting situations

Do you have a Linear Application that we can help with?

Rotary Applications

Roller bearings with high rigidity and highest accuracy are required for use in aircraft protection. The bearings must be able to compensate for thermal expansion.

Solution

Slewing ring LDB80/295 as cylindrical roller bearing made of aluminium with a diameter of 295 mm. A further bearing assembly in the form of a three-point bearing is also used.

.

Solution

Bearing solution used

Bearing assembly type LVB (customized)

Bearing element LEL (customized)

.

Advantages

The LDZ bearing assembly has a radial and axial runout of 0.03 mm. A weight saving is achieved by the light aluminium construction. The load ratings, rigidity and accuracy of the bearing are determined by the raceways. The second bearing has a load angle of 45° (three-point bearing). The outer ring is movable in order to optimally compensate for the thermal expansions that occur.

For the fan of a living room ventilator an absolutely silent bearing must be found. The bearing must compensate for certain manufacturing tolerances of the injection-moulded housing. The housing has a compact design; only a small installation space is available for the bearing used.

Solution

Bearing element LEZ367 with 2.5 mm wire and 6 mm balls.

Bearing solution used

Bearing element LEL (customized)

.

Advantages

To further minimize noise, the ball cage of the bearing is only fitted with every second ball. To facilitate series assembly by the customer, the injection-moulded housing has been optimised. A threaded ring is used to adjust the bearing seat.

The main bearing of the computer tomograph is partly responsible for ensuring that accurate images are delivered. Even at high speeds, it must run quietly and with low vibration. Exact radial and axial runout must be guaranteed..

Solution

A customer specific patented Franke whisper bearing with elastomer. In addition to the high running smoothness, Franke CT bearings have an optimal rotational resistance. The radial and axial runout is a few hundredths of a millimetre, depending on the design and diameter. All Franke CT bearings are adjustable according to customer requirements. The internal elasticity makes the bearing extremely robust even under the toughest operating conditions.

Bearing solution used

Double row angular ball bearing (customized)

Bearing element LEL (customized)

.

Advantages

Extremely quiet running at up to 300 rpm. Noise is dampened by the elastomer (60 dBA). The bearing has a low rotational resistance (< 20 Nm) and electrical insulation between the inner and outer ring. Loads of more than 1,000 kg are possible.