Wire Race Bearings

An ingeniously simple principle

Our Wire Race Bearings are based on a simple yet ingenious principle: Individual race rings made of wire are fitted with a raceway that is designed precisely to match the diameter of the rolling elements. Therefore, the rolling action does not take place directly between the rolling elements and mating structure, but rather with low-friction on the four open race rings. This engineering principle permits free design of the mating structure in terms of its geometry and material selection.

Compact and lightweight

Wire Race Bearings are extraordinarily compact and fit snug in even the tiniest mounting spaces. They are available either as bearing elements (consisting of race rings, rolling element and cage), or as ready-to-use bearing assemblies together with the mating structure. Their compact form and the free material selection for mating structures permit the construction of lightweight designs whose low masses also require less operating power.

Types of Bearings

Product SpecificationProduct Specification

Click Here

Which Bearing?

Product ConsultantNeed help?

Click Here

The Wire race bearing invented & patented by Erich Franke in 1934 is fundamental to all Franke bearing systems. The compact profile of the wire race design enables high accuracy & load capacity & allows flexibility of design. Franke wire race bearing elements consist of 4 raceway wires encapsulating a ball bearing cage.

The wires are offered as drawn or ground profile & are infinitely variable in size. 4 point load capacity allows equal loading in all directions, adjustable preload gives variable controlled rotational resistance in any bearing size from 50mm to 2000mm diameters & above. The LE ranges of wire race bearing elements are offered in 9 size ranges. LEL 1.5, LEL 2.5, LEL 4, LEL 5, LEL 7, precision ground raceways, profiles from 5.9mm to 20.9mm with dynamic load capacities up to 119kN LER 2, LEL 3, LEL 4, LEL 5, use rectangular profile drawn steel wires & offer easier integration & lower cost than ground types.

Sizes from 80mm 1800mm diameters, 7.45mm to 15.75mm sections, & load capacities to 101kN are available. Special constructions for non-corrosive, Aerospace, In-flight, Marine, Medical/Scientific, vacuum, radioactive, & other special environments can be provided.

Benefits

Insensitive to ambient conditions, elastic to shock/impact.

The inner elasticity of the open race rings makes Franke Wire Race Bearings insensitive to ambient conditions, including:

• Temperature fluctuations

• Pressure differences

• Housing torsion

• Vibration

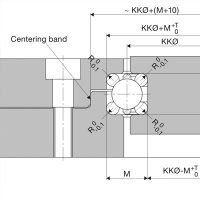

Compact design – minimum mounting space

Franke Wire Race Bearings can be integrated directly into your mating design. Our smallest bearing element requires a mere 4 x 7 mm mounting space.

Compact design – minimum mounting space

Franke Wire Race Bearings can be integrated directly into your mating design. Our smallest bearing element requires a mere 4 x 7 mm mounting space.

4-point system – resilience from all directions

The arrangement of the race rings ensures even loading resilience of the bearings from all directions. This applies equally to the double row angular contact ball bearings.

4-point system – resilience from all directions

The arrangement of the race rings ensures even loading resilience of the bearings from all directions. This applies equally to the double row angular contact ball bearings.

Adjusting ring. Freely adjustable rotational resistance – a preloaded system

Franke Wire Race Bearings can be aligned and adjusted. This takes place using washers, solid adjustment or adjusting ring.

Adjusting ring. Freely adjustable rotational resistance – a preloaded system

Franke Wire Race Bearings can be aligned and adjusted. This takes place using washers, solid adjustment or adjusting ring.

Solid adjustment

Freely adjustable rotational resistance – a preloaded system

Franke Wire Race Bearings can be aligned and adjusted. This takes place using washers, solid adjustment or adjusting ring.

Solid adjustment

Freely adjustable rotational resistance – a preloaded system

Franke Wire Race Bearings can be aligned and adjusted. This takes place using washers, solid adjustment or adjusting ring.

Washers. Freely adjustable rotational resistance – a preloaded system

Franke Wire Race Bearings can be aligned and adjusted.

This takes place using washers, solid adjustment or adjusting ring.

Geared outer and inner ring

All gears available in all qualities on request. We also deliver the required pinions or drives.

• Straight gear

• Angular gear

• Toothed belt gear

• Worm gea

• Special gear

Geared outer and inner ring

All gears available in all qualities on request. We also deliver the required pinions or drives.

• Straight gear

• Angular gear

• Toothed belt gear

• Worm gea

• Special gear

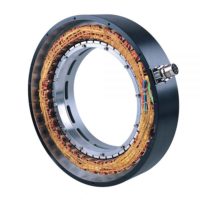

Angular contact ball bearings for highly-dynamic applications

The race rings in the Franke Wire Race Bearings can be arranged individually and also combined to form multi-row bearings. Arranged as angular contact ball bearings, they become highly-dynamic rotational systems for high-end applications.

• Circumferential speeds up to 20 m/s

• Rotational speeds up to 300 rpm

• Elastomer damping for < 60 db(A) (full load)

• Integrated direct drive

Angular contact ball bearings for highly-dynamic applications

The race rings in the Franke Wire Race Bearings can be arranged individually and also combined to form multi-row bearings. Arranged as angular contact ball bearings, they become highly-dynamic rotational systems for high-end applications.

• Circumferential speeds up to 20 m/s

• Rotational speeds up to 300 rpm

• Elastomer damping for < 60 db(A) (full load)

• Integrated direct drive

Free material selection for the mating structure

Franke Wire Race Bearings deliver the requisite rigidity and accuracy of the bearing in almost any mating structure. They carry the principal load. Alternative materials for the mating structure are:

• Steel

• Aluminium

• Cast

• Bronze

• Plastic

•Carbon

• 3D printing

• Non-corrosive

• Special seals (Viton)

• Coatings (ZnFe, electroless nickel, ATC)

• Depending on the material used the weight savings compared with standard steel bearings can be up to 90 %

Free material selection for the mating structure

Franke Wire Race Bearings deliver the requisite rigidity and accuracy of the bearing in almost any mating structure. They carry the principal load. Alternative materials for the mating structure are:

• Steel

• Aluminium

• Cast

• Bronze

• Plastic

•Carbon

• 3D printing

• Non-corrosive

• Special seals (Viton)

• Coatings (ZnFe, electroless nickel, ATC)

• Depending on the material used the weight savings compared with standard steel bearings can be up to 90 %

Free material selection of the bearing element

By standard, Franke Wire Race Bearings are manufactured using tough, hard spring steel. Alternatively other materials can be used for special applications, including:

• Hardened steel

• Non-corrosive

• Coatings (ZnFe, electroless nickel, ATC)

• Non-corrosive balls

• Ceramic balls

• Special cages (non-corrosive, hard fabric, brass)

• Adjusted raceway osculation

• Adjusted carrying angle

• Special grease

• Non-lubricant design

Free material selection of the bearing element

By standard, Franke Wire Race Bearings are manufactured using tough, hard spring steel. Alternatively other materials can be used for special applications, including:

• Hardened steel

• Non-corrosive

• Coatings (ZnFe, electroless nickel, ATC)

• Non-corrosive balls

• Ceramic balls

• Special cages (non-corrosive, hard fabric, brass)

• Adjusted raceway osculation

• Adjusted carrying angle

• Special grease

• Non-lubricant design

Free selection of bearing geometry – design your bearings individually

The housing components are not directly exposed to load from the rolling elements and can be constructed with extremely thin walls. This produces compact and lightweight components in conjunction with the small mounting space the Wire Race Bearings require.

Free selection of bearing geometry – design your bearings individually

The housing components are not directly exposed to load from the rolling elements and can be constructed with extremely thin walls. This produces compact and lightweight components in conjunction with the small mounting space the Wire Race Bearings require.

Constructive Examples

Angular Ball Bearing

Bearing diameter 1060 mm

• Precise large Antifriction Bearings for computer tomographs

• Elastomer insert beneath race rings for smooth and silent running

• Low power input and electrical insulation of the inner and outer ring

• Aluminium mating structure reduces weights and power required

Lightweight Bearing

Bearing diameter 240 mm

• Compact, robust bearing element

• Extremely space saving and light weight design

• Integrated in filigree aluminium design

• Threaded ring for adjustment of rotational resistance

Clean Room Bearing

Bearing diameter 137 mm

• High stiffness and accuracy due to ground raceways

• Special materials ensure optimum function (Ematal)

• Ceramic balls, teflon cage and special lubricant

• Bearing assembly for the clean room class 10.000

Slim bearing

Bearing diameter 30"

• Slim bearing type LSA8 with two race rings

• Easy mounting and manufacturing of the mating structure

• 4-point-system takes loads from all directions

• Free selection of material and design of the mating structure

Hubless wheel

Bearing diameter 414mm

• Double row ball bearing for high stiffness and moment loads

• Adjustable rotational resistance for smooth and easy running

• Center-free design to integrate drive and brake systems

• Small mounting space

Wood Industries

Bearing diameter 113 mm

• Smallest mounting space

• Favourable price for the complete system

• No stick-slip-effect and lowest friction

• Outer ring adjustable individually

Centrifuge

Bearing diamter 280mm

• Slim bearing type LSA5 in double row design

• Race rings and balls non-corrosive, protected against cleaning water

• Easy running and low rotational resistance

• Smallest mounting space

Angular ball bearing

Bearing diameter 1060mm

• Precise large Antifriction Bearings for computer tomographs

• Speed up to 300 rpm

• Integrated direct drive system optional

• Small mounting space, direct integration into the mating structure

Multiple bearing

Bearing diameter 930mm

• Complete customised system including gear

• Customer receives whole system from Franke

• Customised solutions available even at one-piece-orders

• Free selection of the material of the mating structure

Tool Changer

Bearing diameter: 800 mm

• High load capacity from all directions

• Minimum mounting space

• High repetitive accuracy

• Perfectly sealed against dirt and humidity

Blast Furnace

Bearing diameter 850mm

• Temperature range up to 200 °C

• Flat cage made of brass for high temperature

• High radial and axial accuracy

• Optimum adjustment to all interface dimensions

Indexing table

Bearing diameter 380mm

• Highest static and dynamic load capacity

• High accuracy due to ground raceways

• Minimum mounting space

• Cost-effective solution to create a directly driven bearing

Ring loader

Bearing diameter 1200mm

• Special position of wire rings for fast adjustment of rotational resistance

• Outer gear for belt drive

• Labyrinth-seal for protection against cooling water

• Mating structure made of aluminum for light weight and small driving power

Patient bed

Bearing diameter 370mm

• Mating structure in customized design

• Minimum mounting space allows slim design

• Threaded ring for easy adjustment of the rotational resistance

• Rectangular race ring profile for ease machining of the bearing bed

Precision Bearing

Bearing diameter 906mm

• Precision bearing with ground raceways

• Suitable for high temperature, flat cage made of brass

• 60°-angle position of race rings for high radial loads

• Labyrinth-seal for protection against environmental influences

Circular knitting machine

Bearing diameter 930mm

• High accuracy for perfect fabric structure

• Smallest mounting space, direct integration into the mating structure

• Rotary speeds up to 60 revolutions per minute

• Best cost-performance-ration due to long lifetime and favourable price

Machinery

Bearing diameter 560mm

• Classic 4-point-contact-bearing made of steel

• Ground raceways for high load capacity and precision

• Divided outer ring for easy adjustment of the rotational resistance

• Customised design of the mating structure

Tool revolver

Bearing diameter 635mm

• High precision bearing with axial runout < 0,05mm

• Labyrinth- and Viton-seal protection against cooling water

• Plasma nitrided surfaces and hardened gear

• Direct integration into customers design

Aerospace bearing

Bearing diameter 180mm

• Housing parts made of aluminum for light weight

• Easy running with rotational resistance <0,5 Nm

• Insensitive to temperature changes and vibrations

• Labyrinth-seal protection against environmental influences

Bearing for Robots

Bearing diameter 250mm

• Housing parts made of aluminum for light weight

• Smallest mounting space for slim design

• Bearing element type LER3 with rectangular profil for easy mounting

• Customised design of the mating structure

Medical technique

Bearing diameter 1060mm

• Precise large Antifriction Bearings for computer tomographs

• Elastomer insert beneath race rings for smooth and silent running

• Low power input and electrical insulation of the inner and outer ring

• Aluminium mating structure reduces weights and power required

Applications

Cardanic Suspension of Aerial Camera

Requirements

Light, customised bearings are required for the articulation of the cardanic suspension; they must possess high stiffness while

at the same time remaining smooth and with low breakaway torque and rotational resistance. Forces and torques occur from all directions. The bearings must not impede the camera's imaging quality.

Solution

LDB155 on high-strength aluminium with customized bore pattern. Anodized-orange by request of the customer.

Advantages

Bearing material, design and coating based on customer specifications. The 4-point contact bearing can accommodate forces from all directions and is insensitive to temperature fluctuation and vibrations. Smooth bearing with concomitant, high stiffness, at a favorable price.

Cardanic Suspension of Aerial Camera

Requirements

Light, customised bearings are required for the articulation of the cardanic suspension; they must possess high stiffness while at the same time remaining smooth and with low breakaway torque and rotational resistance. Forces and torques occur from all directions. The bearings must not impede the camera's imaging quality.

Solution

LDB155 on high-strength aluminium with customized bore pattern. Anodized-orange by request of the customer.

Advantages

Bearing material, design and coating based on customer specifications. The 4-point contact bearing can accommodate forces from all directions and is insensitive to temperature fluctuation and vibrations. Smooth bearing with concomitant, high stiffness, at a favorable price.

Cardanic Suspension of Aerial Camera

Requirements

Light, customised bearings are required for the articulation of the cardanic suspension; they must possess high stiffness while

at the same time remaining smooth and with low breakaway torque and rotational resistance. Forces and torques occur from all directions. The bearings must not impede the camera's imaging quality.

Solution

LDB155 on high-strength aluminium with customized bore pattern. Anodized-orange by request of the customer.

Advantages

Bearing material, design and coating based on customer specifications. The 4-point contact bearing can accommodate forces from all directions and is insensitive to temperature fluctuation and vibrations. Smooth bearing with concomitant, high stiffness, at a favorable price.

Cardanic Suspension of Aerial Camera

Requirements

Light, customised bearings are required for the articulation of the cardanic suspension; they must possess high stiffness while at the same time remaining smooth and with

low breakaway torque and rotational resistance. Forces and torques occur from all directions. The bearings must not impede the camera's imaging quality.

Solution

LDB155 on high-strength aluminium with customized bore pattern. Anodized-orange by request of the customer.

Advantages

Bearing material, design and coating based on customer specifications. The 4-point contact bearing can accommodate forces from all directions and is insensitive to

temperature fluctuation and vibrations. Smooth bearing with concomitant, high stiffness, at a favorable price.

Satellite Antenna on Seagoing Vessels

Requirements

The bearing requires high stiffness across its entire service life (shock stress due to waves and swell). The system must possess non-corrosive properties and provide constant rotational resistance across temperature ranges from –25°C to +60°C.

Solution

The bearing assembly LDA166 in its steel version with adjusting ring, including coating and LER bearing element.

Advantages

The steel solution delivers constant rotational resistance across the entire temperature range. An additional inlet process with readjustment guarantees high stiffness over the whole service life.

Satellite Antenna on Seagoing Vessels

Requirements

The bearing requires high stiffness across its entire service life (shock stress due to waves and swell). The system must possess non-corrosive properties and provide constant rotational resistance across temperature ranges from –25°C to +60°C.

Solution

The bearing assembly LDA166 in its steel version with adjusting ring, including coating and LER bearing element.

Advantages

The steel solution delivers constant rotational resistance across the entire temperature range. An additional inlet process with readjustment guarantees high stiffness over the whole service life.

Requirements

A concept vehicle is to be motorized by one direct drive unit per wheel. This requires a bearing system with compact mounting space and sufficient load-bearing capacity. The maximum revolutions is 1000 rpm. The balls must be non-magnetic, as they are fitted adjoining the direct drive.

Solution

Four LES0380 – 5/9.525, including ceramic balls.

Advantages

Customized bearings for direct integration in the customer-side design. Accommodation of forces from all sides, including tilting torque. Mounting space designed in cooperation with the customer. Joint assembly of the prototype at Franke.

Requirements

A concept vehicle is to be motorized by one direct drive unit per wheel. This requires a bearing system with compact mounting space and sufficient load-bearing capacity. The maximum revolutions is 1000 rpm. The balls must be non-magnetic, as they are fitted adjoining the direct drive.

Solution

Four LES0380 – 5/9.525, including ceramic balls.

Advantages

Customized bearings for direct integration in the customer-side design. Accommodation of forces from all sides, including tilting torque. Mounting space designed in cooperation with the customer. Joint assembly of the prototype at Franke.

Aircraft Laser Optics

Requirements

Wire race bearings with high rigidity and highest accuracy are required for use in aircraft protection. The bearings must be able to compensate for thermal expansion.

Solution

Bearing assembly LDB80 / 295 as cylindrical roller bearing made of aluminium with a diameter of 295 mm.In addition, another bearing assembly is used in the form of a three-point bearing.

Advantages

The bearing assemvly type LDZ has a running accuracy of 0.03 mm. Weight saving is achieved by the lightweight aluminum construction. The load ratings, the rigidity and the accuracy of the bearing are determined by the races. The second bearing has a support angle of 45 ° (three-point bearing). The outer ring is movable to optimally compensate for the thermal expansions that occur.

Aircraft Laser Optics

Requirements

Wire race bearings with high rigidity and highest accuracy are required for use in aircraft protection. The bearings must be able to compensate for thermal expansion.

Solution

Bearing assembly LDB80 / 295 as cylindrical roller bearing made of aluminium with a diameter of 295 mm.In addition, another bearing assembly is used in the form of a three-point bearing.

Advantages

The bearing assemvly type LDZ has a running accuracy of 0.03 mm. Weight saving is achieved by the lightweight aluminum construction. The load ratings, the rigidity and the accuracy of the bearing are determined by the races. The second bearing has a support angle of 45 ° (three-point bearing). The outer ring is movable to optimally compensate for the thermal expansions that occur.

CT Scanner

Requirements

The main bearing on the computer tomography machine is one of the elements responsible for ensuring that precise images are delivered. It must run quietly and with low vibrations, even at high speeds. It is necessary to guarantee exact radial and axial run-out.

Solution

A customized, patented Franke Flüsterlager® with elastomer.

Besides excellent running, the Franke CT bearings also come with ideal rotational resistance. The radial and axial run-out is just a few hundredth millimeters, depending on the engineering and diameter. All Franke CT bearings can be calibrated to suit customer specifications. The inner elasticity keeps the bearing outstandingly robust, even when exposed to the toughest conditions of use.

Advantages

Extremely smooth running at up to 300 rpm. The elastomer suppresses the noise generation (60dBA). The bearing possesses a low rotational resistance (< 20Nm) and electrical insulation between the inner and outer ring. Loads in excess of 1000kg are possible.

CT Scanner

Requirements

The main bearing on the computer tomography machine is one of the elements responsible for ensuring that precise images are delivered. It must run quietly and with low vibrations, even at high speeds. It is necessary to guarantee exact radial and axial run-out.

Solution

A customized, patented Franke Flüsterlager® with elastomer.

Besides excellent running, the Franke CT bearings also come with ideal rotational resistance. The radial and axial run-out is just a few hundredth millimeters, depending on the engineering and diameter. All Franke CT bearings can be calibrated to suit customer specifications. The inner elasticity keeps the bearing outstandingly robust, even when exposed to the toughest conditions of use.

Advantages

Extremely smooth running at up to 300 rpm. The elastomer suppresses the noise generation (60dBA). The bearing possesses a low rotational resistance (< 20Nm) and electrical insulation between the inner and outer ring. Loads in excess of 1000kg are possible.

Hubless Rim on a Formula Student Race Car

Requirements

The aluminium-carbon rim on an electric race car should be designed to accommodate the drive and braking systems in its center. The bearings used must require very little mounting space and possess a large open center. Plus they need to securely transfer substantial forces and torques.

Solution

Franke Wire Race Bearing, integrated directly in the housing components of the rim as double row angular contact ball bearings. The Wire Race Bearing handles the prevalent loads and works independent of the material used in the mating components. The wires and the rolling elements require minimal mounting space.

Advantages

Space-saving bearing solution with large open center. Its arrangement as double row angular contact bearings permits extremely dynamic movement processes.

Hubless Rim on a Formula Student Race Car

Requirements

The aluminium-carbon rim on an electric race car should be designed to accommodate the drive and braking systems in its center. The bearings used must require very little mounting space and possess a large open center. Plus they need to securely transfer substantial forces and torques.

Solution

Franke Wire Race Bearing, integrated directly in the housing components of the rim as double row angular contact ball bearings. The Wire Race Bearing handles the prevalent loads and works independent of the material used in the mating components. The wires and the rolling elements require minimal mounting space.

Advantages

Space-saving bearing solution with large open center. Its arrangement as double row angular contact bearings permits extremely dynamic movement processes.

Rotary Table Index

Requirements

The bearing used must guarantee smooth and clean operation of the rotary tables in their designated applications, and must also ensure high repeatability precision with simultaneous positioning accuracy.

The system moves heavy payloads.

Solution

Bearing elements LEZ with bearing diameter 400 to 1500mm.

Engineered with a variety of wire races and ball combinations.

Advantages

The Franke LEZ bearing elements used are designed precisely to suit the various loads and hence guarantee smooth and clean movements of the rotary tables. Additionally, the 4-point system has no difficulty withstanding the prevailing loads.

Rotary Table Index

Requirements

The bearing used must guarantee smooth and clean operation of the rotary tables in their designated applications, and must also ensure high repeatability precision with simultaneous positioning accuracy.

The system moves heavy payloads.

Solution

Bearing elements LEZ with bearing diameter 400 to 1500mm.

Engineered with a variety of wire races and ball combinations.

Advantages

The Franke LEZ bearing elements used are designed precisely to suit the various loads and hence guarantee smooth and clean movements of the rotary tables. Additionally, the 4-point system has no difficulty withstanding the prevailing loads.

Circular Knitting Machine

Requirements

The main bearing in the knitting machine plays a crucial role in the quality of the knitted goods. The highest standards are placed in the precision and operating performance of the bearing, despite the high mechanical and thermal load. The required speeds are up to 60 rpm.

Solution

A ground bearing element from the LEL series with a ball pitch diameter of 400 to 1500mm, made of chromium-silicon, ensures even, smooth running, even in the smallest mounting space. High precision of the bearing in axial and radial runout (<0.03mm) and the outstanding surface quality of the raceways ensure a constantly high quality of the machine.

Advantages

LEL with wire diameter of 4mm, ball diameter of 3/8’’, 8, 10 or 12 mm. The carrying angle is 45°; in special cases even 53°, due to the mainly axial load. Standard speed are at 30 rpm, and up to 60 rpm for smaller ball pitch diameters The axial load caused by the machine cylinder is around 4000N, depending on the machine type.

Circular Knitting Machine

Requirements

The main bearing in the knitting machine plays a crucial role in the quality of the knitted goods. The highest standards are placed in the precision and operating performance of the bearing, despite the high mechanical and thermal load. The required speeds are up to 60 rpm.

Solution

A ground bearing element from the LEL series with a ball pitch diameter of 400 to 1500mm, made of chromium-silicon, ensures even, smooth running, even in the smallest mounting space. High precision of the bearing in axial and radial runout (<0.03mm) and the outstanding surface quality of the raceways ensure a constantly high quality of the machine.

Advantages

LEL with wire diameter of 4mm, ball diameter of 3/8’’, 8, 10 or 12 mm. The carrying angle is 45°; in special cases even 53°, due to the mainly axial load. Standard speed are at 30 rpm, and up to 60 rpm for smaller ball pitch diameters The axial load caused by the machine cylinder is around 4000N, depending on the machine type.

Articulated Robot

Requirement

The lightweight robot is used as a service robot and mobile robot. The net weight of the robot is 10kg with a rated load of 3kg. It consists of CFK materials with good rigidity and low mass.

Bearings are planned for use in the movement axes. Their main requirements are also high stiffness, low weight and small mounting space.

Solution

Bearing elements in the LEZ64 and LEL84 series.

Advantages

Bearing elements only require minimal mounting space and are

built in directly to the design of the robot. The material of the

mating structure does not therefore depend on the bearing and

can be freely selected. High bearing strength in all directions.

Articulated Robot

Requirement

The lightweight robot is used as a service robot and mobile robot. The net weight of the robot is 10kg with a rated load of 3kg. It consists of CFK materials with good rigidity and low mass.

Bearings are planned for use in the movement axes. Their main requirements are also high stiffness, low weight and small mounting space.

Solution

Bearing elements in the LEZ64 and LEL84 series.

Advantages

Bearing elements only require minimal mounting space and are

built in directly to the design of the robot. The material of the

mating structure does not therefore depend on the bearing and

can be freely selected. High bearing strength in all directions.

X-Ray Device

Requirements

The curved imaging unit of an X-ray device encloses a gurney.

This so-called C-arch must be light and evenly shaped, also

tiltable by hand.

Solution

Franke Wire Race Bearings as segment bearings.

Advantages

Direct integration of the race segments in the housing components saves space and costs. The segment bearing is set free from clearance and can be moved by hand with a defined resistance.The movement is quiet and even. The 4-point contact bearing easily accommodates the high torque forces in any travel position.

X-Ray Device

Requirements

The curved imaging unit of an X-ray device encloses a gurney.

This so-called C-arch must be light and evenly shaped, also

tiltable by hand.

Solution

Franke Wire Race Bearings as segment bearings.

Advantages

Direct integration of the race segments in the housing components saves space and costs. The segment bearing is set free from clearance and can be moved by hand with a defined resistance.The movement is quiet and even. The 4-point contact bearing easily accommodates the high torque forces in any travel position.

Placement Head for Printed Circuit Board Production

Requirements

Bearing for a high-performance placement head in printed circuit board production with a cycle frequency of 18 start/stop movements per second and up to 120 million revolutions over five years. The service life is defined as ten years. The bearing must be free from clearance in all directions at 70 °C so that the components can be fitted precisely.

Solution

Franke special bearing assembly LDB0110. Aluminium (Dispal) is used as the material for the inner and outer ring. It has almost the same thermal expansion coefficient as steel, facilitating constant unit set values across the entire temperature range.

Advantages

Customer-specific design, which meets all requirements with regard to size, material and mounting dimensions. The integrated bearing element has a small cross section, giving the customer a compact, but nevertheless lightweight design. Franke is the only manufacturer worldwide that can satisfy these specifications.

Mobile Satellite Antenna

Requirements

The main bearing for a mobile satellite antenna must not weigh over 1kg. Smooth running with simultaneous tilting stiffness must be guaranteed.

Solution

Franke bearing assembly LDB200 made of aluminium,

with inner ring geared on the outside.

Advantages

Complete bearing assembly, ready for installation, made of aluminium and with tooth belt gear. Large open center and low mounting space thanks to the compact structure.